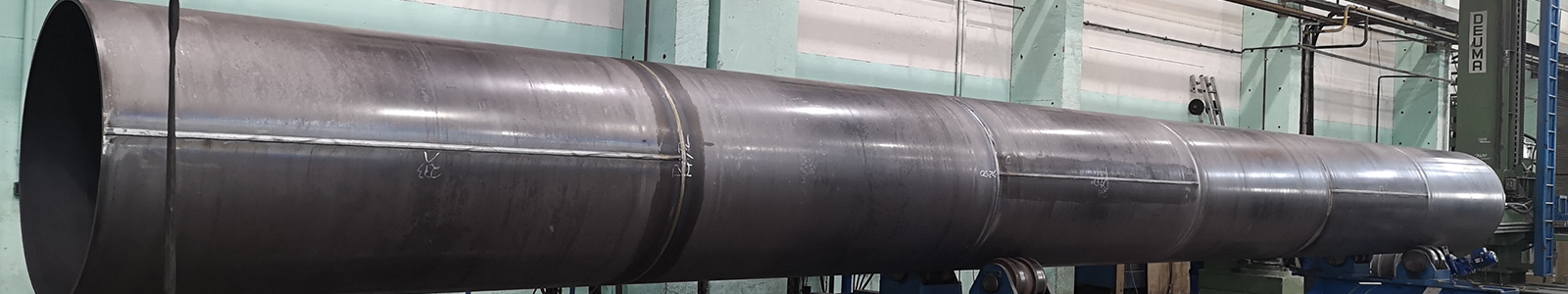

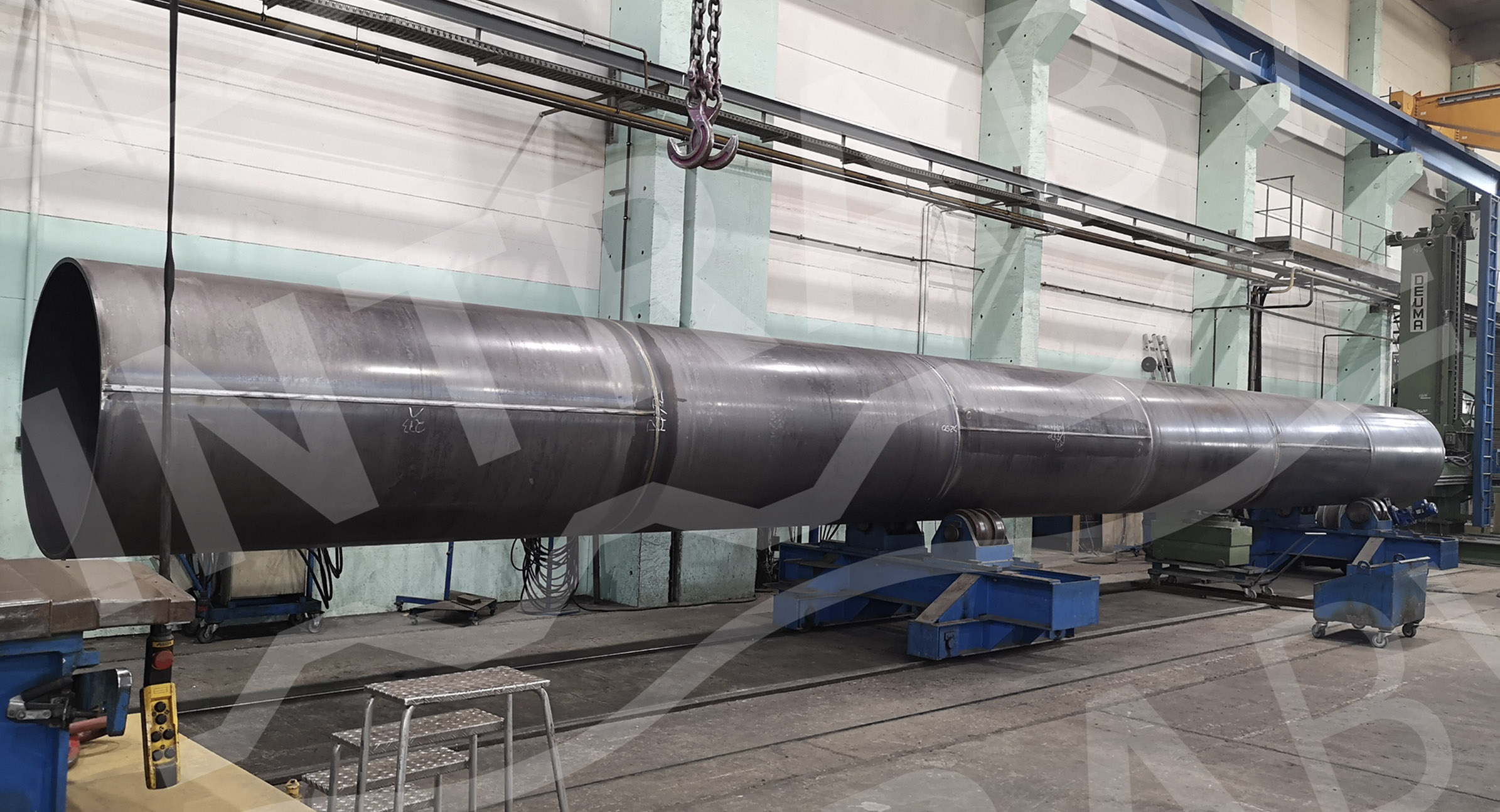

Combined Pipes

With a Combined Pipe, various Pipes with small differences in diameters and/or wall thicknesses are assembled into one Pipe. Here, the demand for different strengths (Wx) and stiffnesses (Ix) can be met along the length of one Pipe. This saves tons of Steel where the Wx and Ix may be lower.

Combined Tubes can be manufactured using all techniques (longitudinal, spiral, seamless). The most common is the longitudinally welded technique.

These Pipes are very suitable for heavy duty applications and are often seen in Mooring Posts or guideways, wind turbines, support structures/ Foundations in the offshore industry.

Optional

- Non-destructive Testing (NDT)

- Ultrasonic testing

- Magnetic testing

- Radiographic examination (X-ray or gamma ray)

- Destructive testing (DO)

- Tensile test

- Chemical Analysis

- Impact test

- Drilling head; design Intra BV, also possible with a large injection lance

- Bell ends

- Footplates

- Various welding options (e.g. mooring post attributes)

- Coating/galvanizing

- CE-marking