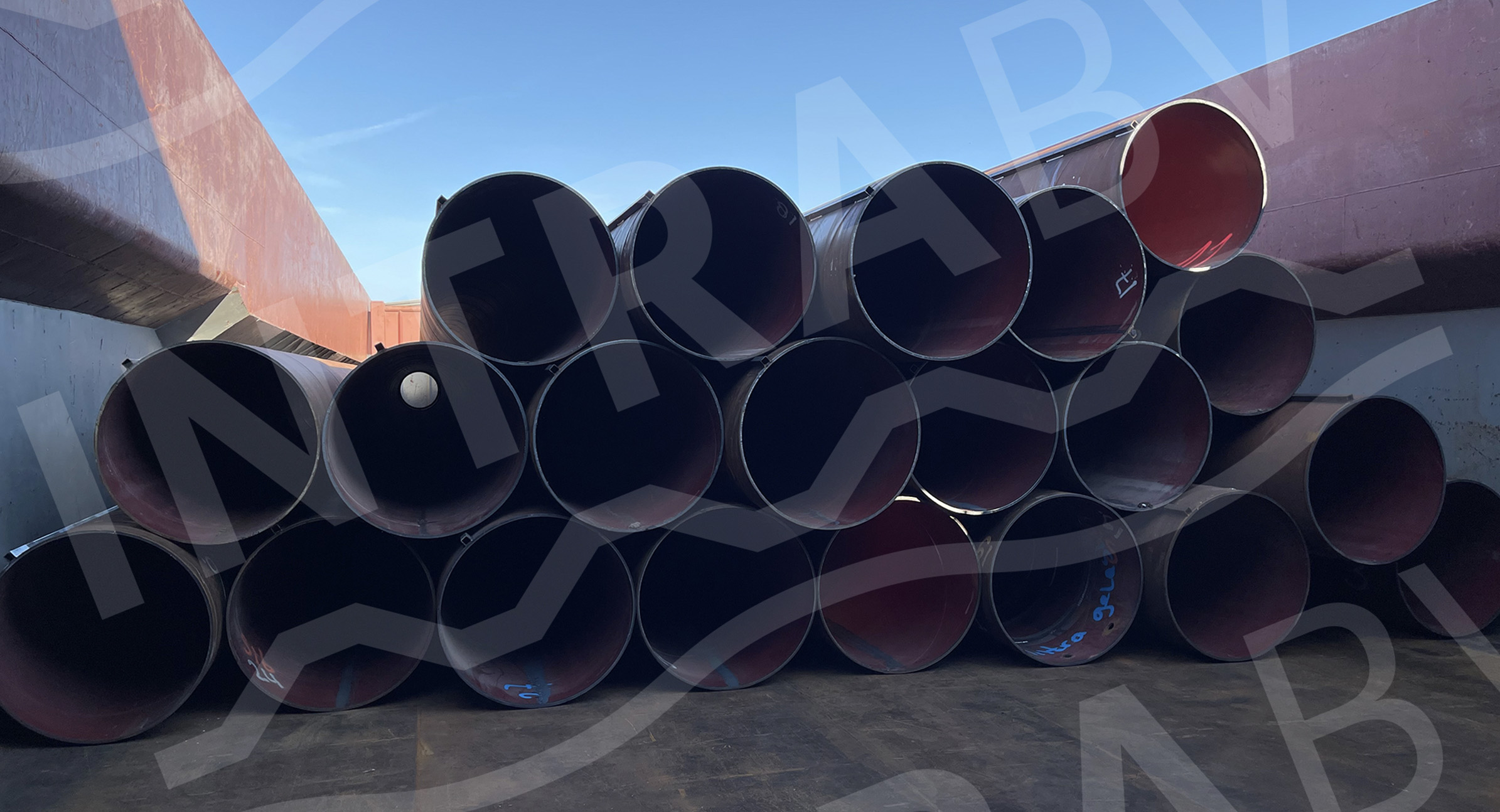

Spirally Welded Pipes

Spirally Welded Pipes are Pipes where the weld runs across the Pipe as a spiral. A coil is rolled out and formed into a pipe-shaped spiral. It is then completely spirally welded. This is a continuous welding process until the coil is unwound. This is the ideal production form for larger projects/bigger quantities with long Pipes and relatively thin wall thicknesses.

Spirally Welded Pipes are very suitable for various constructions as; Combined Walls , (outrigger) Pipes, Mooring Posts/Fenders and Guideways.

Optional

- Non-destructive Testing (NDT)

- Ultrasonic testing

- Magnetic testing

- Radiographic examination (X-ray or gamma ray)

- Destructive testing (DO)

- Tensile test

- Chemical Analysis

- Impact test

- Drilling head; design Intra BV, also possible with a large injection lance

- Bell ends

- Footplates

- Various welding options (e.g. mooring post attributes)

- Coating/galvanizing

- CE-marking